MANLON Spiral Cable

MANLON, a trusted leader in the industry, excels in crafting spiral cables tailored to meet the specific needs of harsh environment applications.

These cables are meticulously engineered to withstand the rigors of extreme conditions, ensuring reliable and durable performance in demanding settings.

By leveraging cutting-edge manufacturing capabilities, MANLON ensures prompt delivery of spiral cables to businesses worldwide, catering to the diverse requirements of various harsh environment applications.

MANLON Spiral cable / Coiled cable - Harsh Environments

Key Features:

– Expertly designed to address the challenges of cable management in harsh environment applications

– Utilizes premium materials for enhanced durability and extended lifespan in demanding conditions

– Engineered to withstand the rigorous stress and strain typical of harsh environment applications

– Geared towards enhancing safety and efficiency in harsh environment operations

– Customizable to meet the specific needs of harsh environment applications

Reasons to Choose MANLON for Spiral Cables:

– Recognized as a trusted manufacturer with a strong reputation in the harsh environment industry

– Operates an in-house production facility for prompt delivery to harsh environment customers

– Committed to upholding the highest standards of quality and customer satisfaction in the harsh environment sector

– Offers competitive pricing for cost-effective solutions for harsh environment applications

– Employs a skilled team of professionals to provide personalized support to harsh environment customers

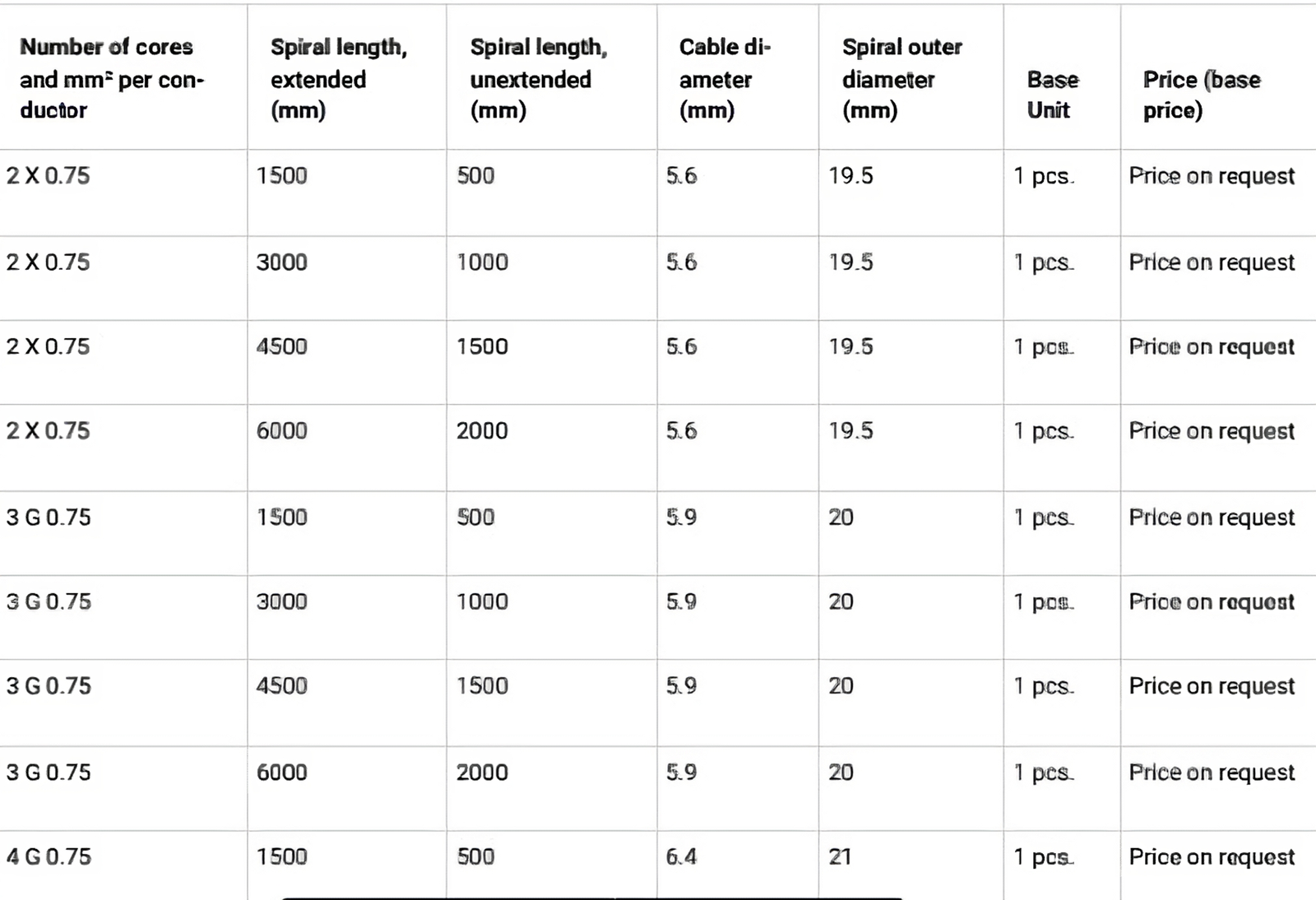

MANLON Coiled Cables are available in Coss sections ranging from 0.25 mm² to 16 mm² and much more.

MANLON Retractable cables are made in working (Extendable) lengths from 1 Meter to 20 Meter.

MANLON spiral cable is manufactured using formulated thermoplastic polymer - PVC / PA/ PUR/ TPE/ TEFLON as core and outer jacket.

Manufacturing Since 1987

Spiral cables provide substantial advantages to applications in harsh environments by ensuring reliability and durability in demanding conditions.

These cables are engineered to withstand the rigors of extreme environments, including vibrations, temperature fluctuations, and corrosive conditions.

This robustness enhances workplace safety and safeguards the welfare of personnel in harsh environment facilities.